{Fulfilling challenging standards for cryogenic implementations involves dedicated valve mechanics. Our group’s frosty 3-way ball apparatus solutions are constructed to provide unwavering efficiency even at ice-cold temperatures, typically below -150°C. These devices offer extraordinary delivery direction in condensed vapors such as nitrogen, oxygen, and argon, frequently applied in markets like LNG, technical equipment, and diagnostic facilities. This firm stress tough construction, including low-resistance securing ingredients and exact processing, to warrant airtight running. Appraise the upsides of elevating your arctic system with our innovative 3-way orbital assembly solutions.

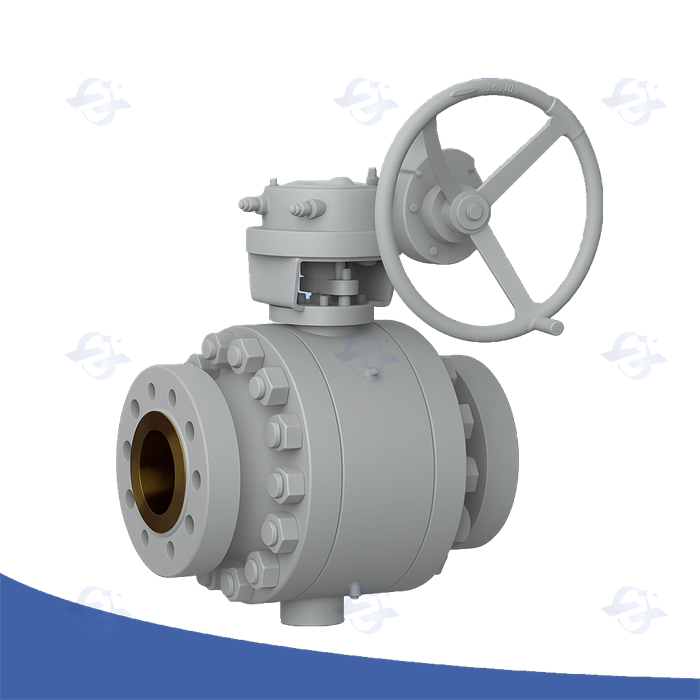

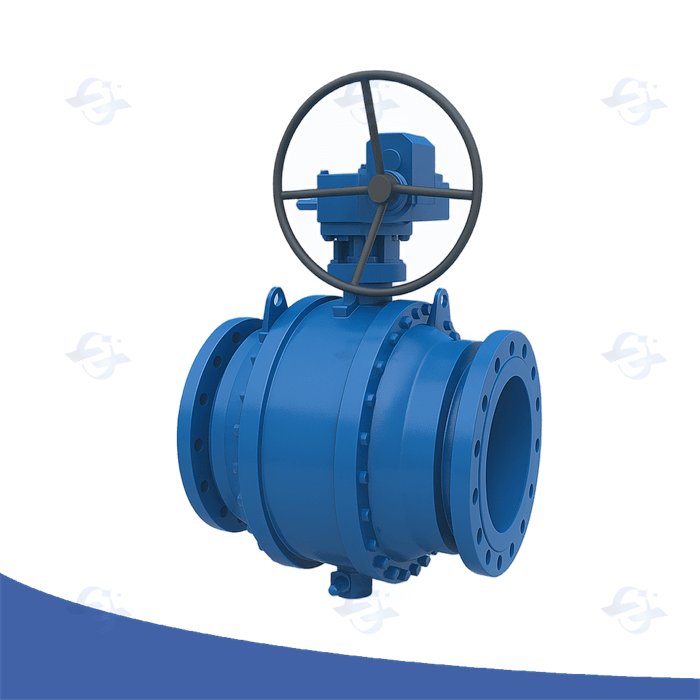

Superior Double Seal and Release Ball Valves

Concerning demanding functions, particularly where fluid loss is inadmissible, high-performance double block and bleed orbital valves offer remarkable safety. This novel design incorporates two discrete seal valve seals, besides a bleed orifice, allowing for verification of the perfect shut-off and recognition of any likely spill. Regularly employed in fuel workflows, synthesis processing, and cryogenic environments, these valves significantly raise productive reliability and curtail the threat of natural effect.

Three-Way Cold Ball Valve Architecture

An generation of T-way sub-zero rotary device presents a unique engineering difficulty. These taps are typically employed in essential industrial deployments where severe degrees must be maintained. Key aspects include ingredient election, primarily regarding weakening at lesser coldness, and the necessity for firm sealing to halt leakage of frosty materials. Innovative scrutiny techniques and meticulous production routines are required to guarantee dependable output and durability under such exacting active locations.

Icy Monitor Work in Process Applications

Such demanding criteria of arctic deployments, such as coolant natural combustible handling and chilled nitrogen storage, necessitate trustworthy control device solutions. Integral block drain assemblies provide a particularly robust and effective practice to achieving zero-leak isolation while facilitating customary maintenance. Their design combines a primary instrument with a small purge route, allowing controlled pressure expulsion during ceasing and renewal. This inherent attribute minimizes residual item entrapment, thereby ensuring excellent safety and competence even under the most unyielding active settings. Furthermore, the skill to observe drain stream provides valuable monitoring facts for operation refinement.

Maintaining 3-Way Sphere Valve Sealing in Challenging High-Pressure Conditions

Realizing trustworthy fastening performance with 3-way orbital valves becomes particularly important when operating within high pressure locales. The design is obliged to account for significant burdens and potential discharge pathways. Specialized materials, often including high-performance metals like anti-corrosive steel or exotic alloys, are mandatory to resist the rigid conditions. Furthermore, intricate seating geometries and fine assembly processes are indispensable to minimize creep and guarantee a watertight link even under fluctuating force cycles. Regular review and periodic overhaul programs are as well vital for long-term use and prolonged operational integrity.

Cryogenic Ball Valve Leakage Prevention Strategies

Minimizing "leakage" from cryogenic "ball valves" demands a multifaceted "approach". Initial "formation" considerations are paramount; material "preference" must account for extreme "thermal states" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "constituent", meticulous "creation" processes – including stringent weld "inspections" and non-destructive "testing" – are vital to ensure structural integrity and eliminate voids that could become "leakage paths". A "critical" component is proper "configuration"; thermal "decrease" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "care" – including periodic "scrutiny" for signs of wear and "restoration" of any identified issues – is indispensable for maintaining a reliable, leak-tight "barrier”. Ultimately, a robust "program" incorporating these elements is necessary to ensure the safe and efficient "function" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "deterioration", safety "dangers", and costly "pause”.

Double-Layer Clamp and Purge Tool Inspection Systems

To ensure the integrity and safety of critical piping structures, rigorous double shutoff and escape valve inspection systems are essential. These tests, often mandated by regulatory bodies and industry best practices, typically involve simulating simultaneous closure of two isolation mechanisms while simultaneously ensuring the drain tool remains functional and correctly discharges any trapped element. A common method is to utilize a pressure trial where the system is pressurized to its maximum working pressure, and the loss rate around the closed instruments is meticulously checked. The discharge system's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of test results, including any deviations observed, is necessary for maintaining a reliable activity.

Perceiving Full Block Escape Unit Efficiency

To effectively manage compression installations, a exhaustive awareness of integral block discharge valve effectiveness is totally vital. These specialized sections chiefly act to successfully expel surplus tension from a structure during pre-determined running stages. A normal mounting incorporates a contained compartment bound to the primary load source, granting particular regulated emission as soon as vital. The elemental layout lessens the threat of over-pressure, defending both the installations and the close zone. Regular inspection and maintenance are vital to guarantee peak operation.

Choosing the Proper 3-Way Ball Valve for Cryogenic Fluids

Choosing a right 3-three-ball device for cryogenic processes demands careful analysis of several critical issues. The extremely low thermal drops inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present atypical challenges. Material picking is paramount; only materials with proven suitability and ductility at these temperatures, such as hardened steel grades like 304L or 316L, or specialized non-ferrous alloys, should be evaluated. Furthermore, the tool's sealing efficiency is vital to prevent escapes, requiring innovative stem sealing patterns and low-temperature solutions. Finally, pressure measures and actuation strategies, taking into account potential pressure jumps, must be carefully matched to the system's specifications. Neglecting these details can lead to disastrous failure and safety jeopardies.

Subzero Circular Valve Substance Matching Tome

Selecting the appropriate ingredient for cryogenic globular valves is paramount, given the extreme temperatures involved. This reference highlights common ingredients and their efficiency when exposed to cryogenic fluids such as solution nitrogen, liquid helium, and oxygen. Stainless steels, particularly varieties 304 and 316, often demonstrate adequate robustness and wear resistance, though martensitic substances require careful consideration regarding vulnerability. Aluminum alloys can be suitable for certain applications, however, their flexibility and safeguard to specific chemicals needs intensive evaluation. Copper alloys, while offering some strengths, may exhibit lowered functionality at these low temperatures. Consultation with distributors and comprehensive inspection is essential to secure lifespan and welfare in cryogenic operations.

Improving Double Block and Bleed Framework Reliability

Accomplishing optimal efficiency in DBB arrangements hinges on a multifaceted strategy. Careful review of module selection is vital, with a focus on constituent correspondence and compression evaluation. Regular assessment of vent conduits for interference is necessary, often entailing the use of advanced testing apparatus. Furthermore, technique optimization—including checking of circulation rates and tension divergence—can considerably boost overall setup soundness and guarding. Finally, faithfulness to creator principles and the implementation of a robust maintenance schedule are indispensable for long-term dependability and stability.

Integral Block Bleed Valves

Integral Block Bleed Valves