Inside the scope of industrial workflows, upholding the completeness and efficiency of conduits is crucial. Assembling of dirt within pipelines can markedly block liquid throughput, reduce output standard, and amplifies maintenance costs. To handle these complications, tube cleansing methods have sprung up as preeminently adept cures for smooth line cleaning. A gadget, commonly a cylindrical gizmo, is moved through the conduit, adequately cleaning build-up and ensuring ultimate output

Tube sanitation systems grant various merits. They are versatile, equipped for purifying passages of assorted extents and elements. Furthermore, they are productive, accomplishing the function in a fairly fast timeframe. By curtailing downtime and strengthening pipeline performance, pipeline cleaning systems facilitate monetary advantages and enhanced operational yield

Contamination-Free Pipeline Approaches:

Protecting pipeline freshness is vital for affirming product safety and caliber of supplied wares. Sanitary pigging approaches supply a stable way to accomplish this intention. Pigs, particular tools, are installed into pipelines to scrub by removing residues and waste

- Myriad models of sanitary pigs are found, each created for fixed cleaning tasks.

- These pigs are assembled from constituents that satisfy stringent hygienic standards.

- Periodic sanitary pigging activities promote preventing product impurity, increase pipeline survival, and augment overall productivity.

Modern Pigging Approaches for Top Operation

Within the area of tubing servicing, innovative pigging techniques have materialized as a primary technology for achieving optimum performance and safety. These groundbreaking systems leverage smart layouts and operations to competently flush, analyze, and preserve channels from corrosion. From advanced pigs armed with concurrent recording tools to designed pigging equipment built for difficult tasks, evolution in this discipline is continually pushing boundaries. By adopting these forward steps, executives can materially raise pipeline reliability, cut down downtime, and maximize operational operations.

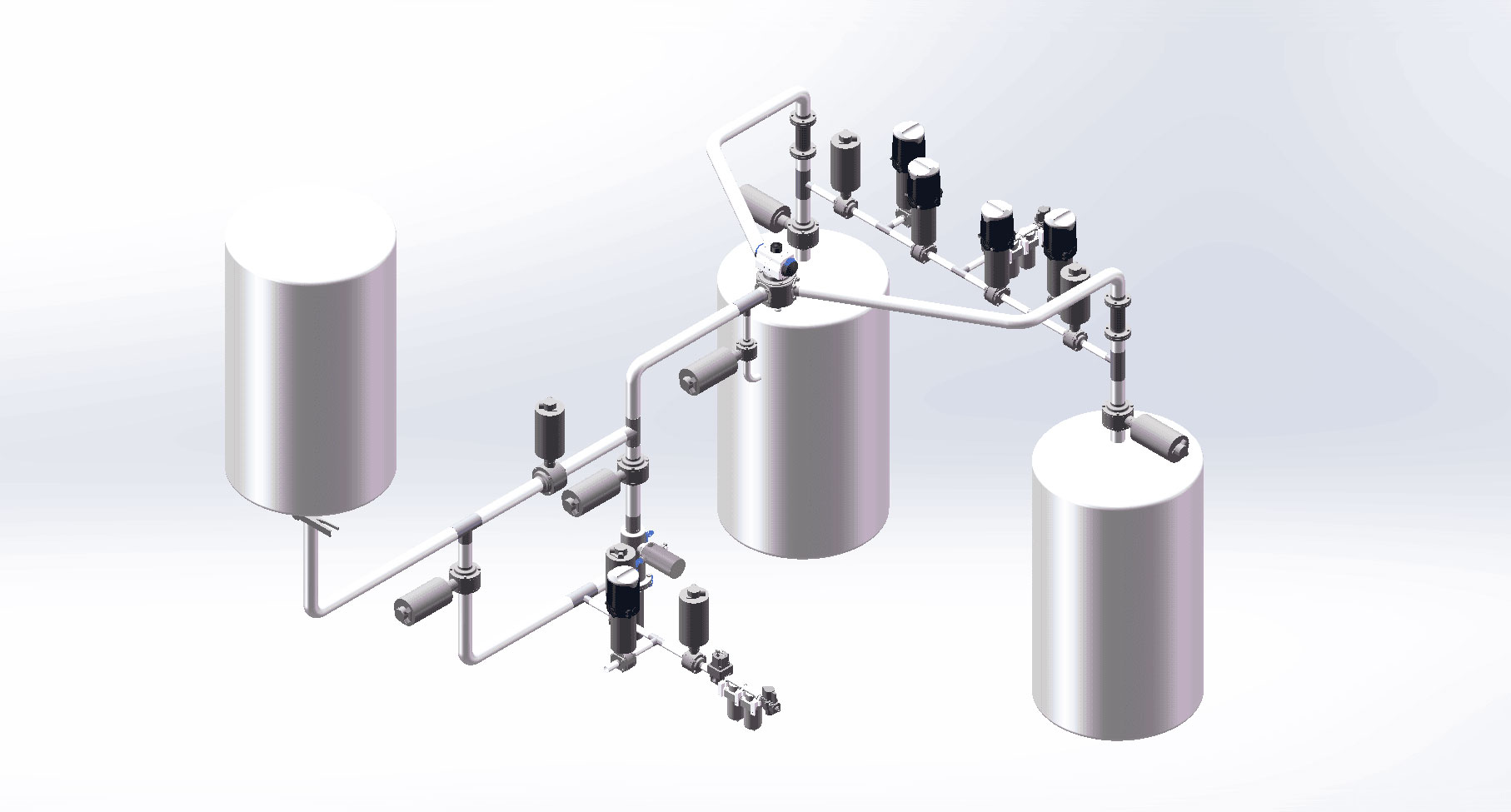

Inclusive Pigging Scheme Engineering and Setup

A full-scale pigging system embodies a critical methodology for pipeline overhaul. This mechanism incorporates the introduction of purpose-built apparatus called pigs, which move through passages to disinfect, survey, and preserve their condition. The blueprint focuses on criteria such as line width, fabric, pig model, and operational required features. A well-conceived system secures productive pigging missions while limiting downtime and potential injuries. Installation methods demand careful setup, skilled operators, and strict adherence to safety measures to confirm a safe and fruitful conclusion

Mechanical Pigging Instruments for Broad Employments

Industrial pigging systems are important mechanisms utilized across a comprehensive spectrum of industries. These implements assist risk-free and advanced sanitizing, assessment, and service of channels and other hollow edifices. Pigging embraces introducing dedicated tools known as pigs through pipes to complete multiple functions. Classic types of industrial pigging tools contain cleaning pigs, inspection pigs, and shipment pigs. Cleaning pigs are engineered to displace debris, build-up, and defilements from pipelines. Inspection pigs are loaded with gadgets that harvest information about the condition of pipe coatings. Transport pigs are operated to move materials through pipelines. The use of industrial pigging products furnishes numerous benefits, such as lessened downtime, heightened pipeline strength, and increased operational output. These equipment are generally applied in areas such as oil and gas, water treatment, chemical production, and food manufacturing.Extensive Pipeline Pigging Manual

Pipeline pigging is an vital technique used within the oil and gas realm to survey pipelines. This crucial task requires launching engineered apparatuses, dubbed pigs, into the pipeline. Pigs are constructed to traverse the extent of the pipeline, completing various jobs.

Some forms of pigs are on call, each built for a designated objective. Common applications of pipeline pigging include evaluation for defects, decontamination, and pipeline rehabilitation.

- Gains of Pipeline Pigging

- Consequences on Operational Efficiency

- Classes of Pipeline Pigs

Dependable Sanitation using Pigging Processes

Pigging mechanisms supply a effective answer for ensuring sanitation inside tubes. These methods utilize specially designed pigs that operate through the pipeline sequence, quickly extracting contaminants. The technique is especially helpful for fields that require rigorous hygiene measures. Pigging technologies yield a affordable and rapid approach for cleaning passages, lowering the threat of infection.

Choosing Pigging Hardware for Custom Specifications

Pigging devices plays a pivotal role in competent pipeline performance. When choosing pigging machinery, it is mandatory to consider the individual needs of your purpose. This comprises evaluating details such as pipeline dimension, flow velocity, product designation, and management specifications.

Plenty of pigging types are offered, each developed for distinct reasons. For instance, some pigs are developed for checking, while others are deployed for removing impurities or isolating product collections.

Also, pigging equipment units should be suitable with the delivered material.

It is typically advisable to connect with a advisor in pigging technology to validate that you choose the most ideal equipment for your customized requirements.

Systematic Pipeline Cleansing - A Value-Adding Approach

Flow line pigging present a expansive range of positive points for industries utilizing channels. By effectively washing and checking conduit interiors, pigging systems augment operational efficiency and decrease maintenance outgoings.

A leading positive of pigging systems is their skill to clear fouling such as dirt, debris, and decay products. This scheduled sanitation affirms frictionless pipeline passage and reduces costly downtime.

Additionally, pigging systems can be used to check the soundness of pipelines, detecting prospective faults before they expand into major difficulties. This preemptive process promotes to prolong durability of pipelines and lower overall maintenance budgets.

Preserving Hygiene in Pigging Workflows

Pig farming methods substantially lean on appropriate hygiene regulations to diminish the passage of illness. Adhering to rigorous hygiene standards maintains a nutritious surroundings for pigs, thus yields optimal health outcomes and production.

Routine cleaning and disinfection of quarters is fundamental to block the spread of harmful bacteria. Proper manure management also plays a key part in preserving hygiene.

As pigging products well, {workers